Chassis – arm – electronic integration (I)

One of the most complex tasks of the project is the integration between the chassis, the arm that moves the mine detector and the integration with all the electronics of the rover.

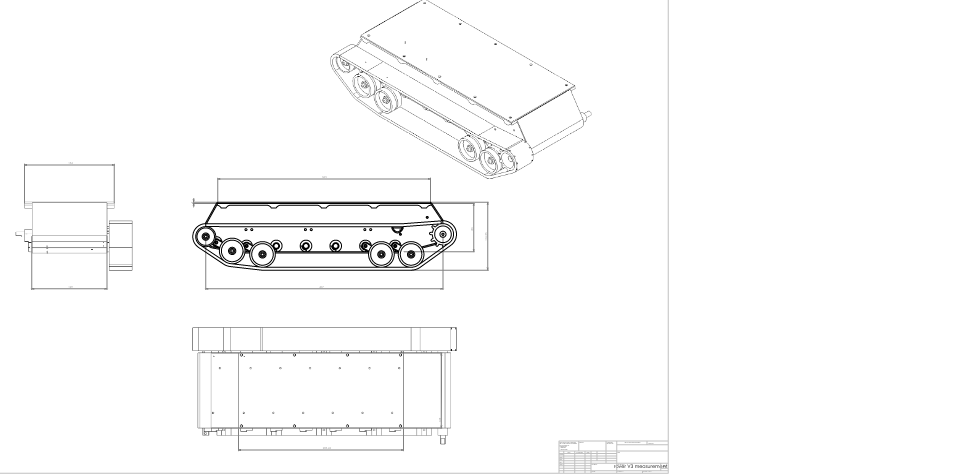

The first step we have taken is to have the specifications of the new rover. The French team that leads the chassis part has created with a CAD program the dimensions of our prototype and has disseminated it to the members of the other teams. Below is a picture about the dimensions of our new rover:

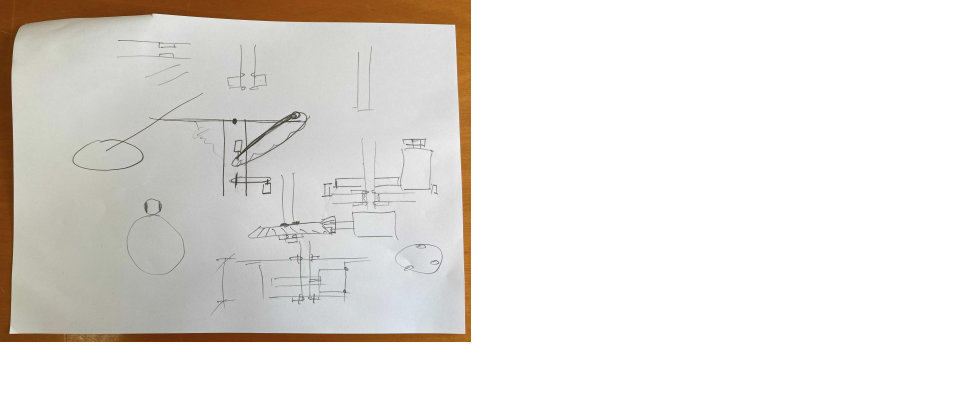

Once these first designs were received, we dedicated ourselves to making sketches on how to efficiently integrate the arm and the chassis. Numerous sketches were made in a brainstorming process to decide which would be the most suitable model for our needs.

Below is a sketch by Manuel Rodriguez, engineer for the Spanish team:

Another challenge is deciding what type of motors to use. The Spanish team for its prototype has chosen to test with Nema-17 motors used in 3D printers for several reasons, among which are:

- They are very cheap.

- Performance and reliability are excellent.

- They are robust.

- They are easily integrable with Arduino, Raspberry Pi and other controllers.

- There is a lot of documentation and projects that serve as a base and help.

Another reason for using stepper motors is that the degrees and their movement can be controlled by software, therefore it is not necessary to use limit switches or any other element that limits the movement of the arm. Simply by software you can control their movements and speed.

They are also “slow” motors. Our rover does not have to be fast since it will have to move through mined areas, which makes precision prevail over speed.

Below is a video of a first electronic assembly with Arduino controlling the movement of the arm:

For the realization of the robotic arm that controls the sensor we have based on a development by Florin Tobler available on Thingiverse. For a first approach to what our robotic arm will be we will need a series of parts that are shown below:

We know that the Florin Tobbler design will not be our final design but it can serve as the basis for redesigning an arm that can be integrated into our rover.

As you can see in the DEMETER project we have used a bottop up design strategy, first creating and testing different devices and models and then integrating all this knowledge into our rover.

This is the way students learn the most. They can learn in this way how the rover works in depth.